1. The Problem: Operational Downtime Due to Knackered Mining Equipment

Underground coal mining demands reliable heavy machinery; even minor failures cause significant operational hold-ups, impacting productivity. Meadow Industries, experts in equipment maintenance, part fabrication, and precision machining, faced this with a crucial miner indexer.

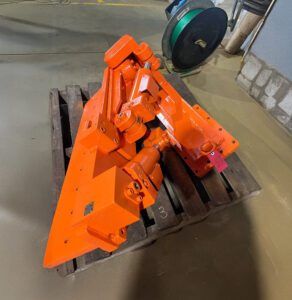

The indexer, vital for continuous coal cutting, suffered performance degradation due to wear on its hydraulic cylinders and associated parts. This led to sluggish operation, inconsistent positioning, and potential breakdown, directly impacting a client’s extraction targets and necessitating an urgent, effective solution.

2. The Solution: A Thorough Inspection and Comprehensive Overhaul

Recognising the criticality, Meadow Industries undertook a detailed inspection of the indexer’s hydraulic system, identifying all wear, damage, and potential failure points, including cylinders, bushes, and pins.

A comprehensive overhaul strategy was implemented:

- Complete Cylinder Overhaul: Full disassembly and replacement of worn internal components with durable parts suited for the harsh underground environment.

- Bush Replacement: Replacement of all worn bushes in the hydraulic linkages with precision-engineered new ones for smooth, accurate movement.

- Pin Replacement: Substitution of worn, corroded, or deformed pins with new, hardened ones to restore structural integrity.

- Remachining, Welding, and Boring: Restoration of worn components like cylinder rods and mounting points to original specifications through expert remachining and certified welding, followed by precision boring for accurate alignment.

3. The Outcome: Restored Performance and Enhanced Reliability

The comprehensive overhaul restored the miner indexer to excellent condition, potentially exceeding its original performance. Meticulous attention to detail and quality replacement parts ensured significantly improved operational efficiency and reliability.

The fully overhauled indexer was successfully reinstalled, promptly returning to optimal underground performance, allowing the client to resume coal cutting without further delays.

4. Key Benefits of Meadow Industries’ Overhaul Service:

This case study highlights the advantages of choosing Meadow Industries for critical equipment overhauls:

- Expertise and Experience: Deep understanding and technical skills gained from years of serving demanding industries like mining.

- Comprehensive Capabilities: Integrated maintenance, fabrication, and machining provide a streamlined overhaul solution.

- Swift Turnaround: Commitment to a rapid and reliable service minimises operational disruption.

- Bespoke Solutions: Tailored procedures to meet specific application needs, ensuring optimal equipment longevity.

- Enhanced Reliability: Thorough inspection and high-quality workmanship lead to equipment with improved durability and performance.

By addressing this critical operational challenge, Meadow Industries demonstrated the value of their expertise and commitment to providing dependable solutions for the Australian mining sector, ensuring vital equipment is ready for demanding tasks.